细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

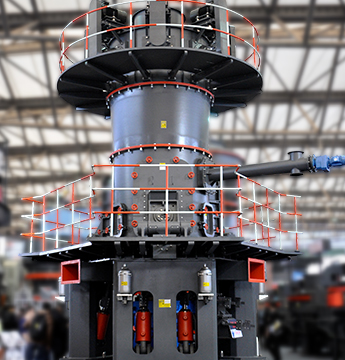

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Bond Mill Work Index Database Jktech Benification Of Iron Ore Youtube

SAG Mill Design and Benchmarking Using Trends in the

This paper describes some of the major trends in JKTech’s database of comminution circuit surveys, and how the variability inherent in data obtained from productionscale mills can 2015年6月6日 — This Grindability Test or Bond Ball Mill Work Index Procedure is used to determine the Bond Work Index of minus six mesh or finer feed ore samples These equation application methods are used to Bond Work Index Procedure and Method2024年6月19日 — BOND ROD MILL GRINDABILITY TEST The Bond Rod Mill Grindability Test is also performed according to the original Bond procedure It requires 15 kg of SGS MINERALS SERVICES – T3 SGS 960 112009Since its introduction in the 1960s, the Bond Ball Mill Work Index (BBMWi) parameter has been extensively used in predicting ball mill power draw Use of Work Index Along with JK Bond Ball Mill Test JKTech

2FD{P}PC]854]XQ.jpg)

Comparison of Ore Hardness Measurements for

2021年1月14日 — • SAGDesign (SAG to T80 12 M followed by Bond BM Wi on SAG ground ore) • Bond Ball Mill Work Index (Crushed Feed) • Specific Gravity (part of the 2021年6月17日 — It is a wellknown fact that the value of the Bond work index (wi) for a given ore varies along with the grinding size In this study, a variability bysis is carried out with the Bond(PDF) Variability Study of Bond Work Index and Bond's work index is one of the mostly widely used metrics of mineral grindability In spite of its ubiquity, users are often not aware of the nuances of the work index family: what are BOND'S WORK INDEX: WHAT IT IS AND WHAT IT ISN'TThe commonly used grindability tests included in the database are the Bond work indices for ball milling, rod milling and crushing; the drop weight test results A, b, A×b, DWi, Mia, Mic, Mih(PDF) BOND'S WORK INDEX: WHAT IT IS AND

A new approach to the calculation of bond work index

2021年5月1日 — The Bond work index (BWI) is a wellknown method used when selecting comminution equipment, to evaluate the grinding efficiency and to calculate the required 2018年12月19日 — Bond work index (Standard FC Bond work index) The crushed sample that was smaller than 335 mm — smaller than 6 mesh — was subjected to Bond work Development of process for beneficiation of lowgrade 2015年6月19日 — This Table of Ball Mill Bond Work Index of Minerals is a summary as tested on ‘around the world sample’ You can find the SG of each mineral samples on the other table [table “” not found /] Source 1: Table of Bond Work Index by MineralsAn improved method using less mass compared to the Bond Ball Mill Work Index test The JK Bond Ball Mill (JKBBM) test, is a locked cycle grindability test conducted using a standard laboratory Bond Ball Mill with the same steel ball charge and material feed size (100% passing 335 mm) as the Bond Ball Mill Work Index test The test requires Comminution testing JKTech University of Queensland

Effect of magnetite content on Bond work index and

2018年4月28日 — Grinding is one of the most costly operations in the mechanical breaking and mining Determination of the breakage characteristics and preconditioning is important to increase the grinding efficiency Investigations of the seismic, mechanical and breakage properties of iron oxides are very important parameters for investigating the rock an average work index of 155 kWh/t A very broad range of results was received, characterising the ‘standard ore’ from medium to very hard A disappointing result considering the reliance on this test globally for design and optimisation An improved method using less mass compared to the Bond Ball Mill Work Index testJK Bond Ball Mill Test JKTech2024年4月26日 — The final stage in iron ore processing is ironmaking, where the iron ore is transformed into molten iron through a process called reduction The most common method of ironmaking is the blast furnace route In a blast furnace, iron ore, coke (carbon), and fluxes (limestone or dolomite) are loaded into the furnace from the topIron Ore Processing: From Extraction to Manufacturing2024年9月24日 — In the past, a lot of experimental research work on this type of iron ore beneficiation, including reduction roasting – weak magnetic separation process of the selection index is relatively good, but because of its technical difficulties is the need for ultrafine grinding, and the current conventional beneficiation equipment and chemicals Various Types Of Iron Ore Beneficiation Processes

.jpg)

Beneficiation of Iron Ore 911Metallurgist

2016年5月24日 — Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per 2013年7月15日 — When Erf/Erp is greater than 129, the work index increases as the product size decreases, and when Erf/Erp is less than 129 the work index decreases Eq (8) suggests that a standard work index Bond Work Index FormulaEquation2020年6月8日 — The bond work index test obtained high work index 5260 kwh/t and consumed power 1172 kwh/t to grind one ton of low grade iron ore and this attributed to the high concentration and hardness of Characterization and Bond Work Index Determination of Low JKTech Comminution Analyst Matt Weier will be travelling to Santiago for Procemin 2018 to present his paper Accuracy of the Bond Ball Mill Test and Its Implications ProceminGeomet is a forum where professionals can JKTech Comminution Analyst travels to Santiago

.jpg)

Iron ore pelletization ScienceDirect

2015年1月1日 — Iron ore lump, sinter, and pellets comprise the main burden of modern blast furnaces However, sinter and pellets are now the dominant blast furnace burden, because the natural lump supply has declined dramatically due to depletion of the world's highgrade competent iron ore resources2024年3月6日 — Iron ore reserves are distributed worldwide, with major deposits found in Australia, Brazil, and China Australia holds the largest reserves, followed by Brazil These countries also dominate global iron ore production, supplying a significant portion of the world's demand Other notable iron ore producers include India, Russia, and South AfricaIron Ore: The Foundation of Steelmaking MarketsThe commonly used grindability tests included in the database are the Bond work indices for ball milling, rod milling and crushing; the drop weight test results A, b, A×b, DWi, Mia, Mic, Mih and (PDF) BOND'S WORK INDEX: WHAT IT IS AND WHAT IT Dry iron ore beneficiation is without doubt currently being driven forward by Vale in Brazil The company wants to increase its capacity from 340 Mta iron ore at present to 450 Mta in future, dry beneficiation is to be further increased by 10 % from 60 % at present Dry beneficiation capacity will increase by around 110 MtaDry beneficiation of iron ore Mineral Processing

.jpg)

Characterization and Comminution Studies of LowGrade Indian Iron

2019年1月31日 — Banded hematite quartzite (BHQ) and banded hematite jasper (BHJ) ores represent a promising potential iron ore resource in the near future The hematite and quartz in BHQ and the hematite and jasper in BHJ are closely related and require fine grinding for the liberation of hematite phases The present study investigates the mineralogical 2022年1月1日 — Iron ore is one of the main raw materials to make steel About 98% of the mined iron ore is used to make steel either by the blast furnace—basic oxygen furnace (BFBOF) route or through the electrical arc furnace (EAF) route The majority of world crude steel is made from the BFBOF minution and classification technologies of iron ore3 天之前 — Iron Ore Price: Get all information on the Price of Iron Ore including News, Charts and Realtime QuotesIron Ore PRICE Today Iron Ore Spot Price Chart Live Price of Iron Microbially induced iron ore formation has been confirmed at Gunma iron ore mine, Japan [21] Ubiquitous microorganisms inhabiting iron ore deposits are useful in iron ore beneficiation (eg, removal of alkalis, silica, clays, phosphorous, and alumina) Because the presence of phosphorous in the iron ore promotes bacterial growth (as an energy Ore Beneficiation an overview ScienceDirect Topics

.jpg)

JK Bond Ball Mill Test now able to be licenced to more JKTech

After offering the JK Bond Ball Mill (JKBBM) Test in house for some years, and with over 500 tests performed, JKTech is pleased to announce the JKBBM is now available to be licenced to other commercial laboratories Initially developed and validated by researchers at the Julius Kruttschnitt Mineral Research Centre (JKMRC), the JKBBM Test reduces The various advantages of iron ore pellets are given below Iron ore pellet is a kind of agglomerated fines which has better tumbling index when compared with the iron ore and it can be used as a substitute for the iron ore lumps both in the BF and for DRI production Pellets have good reducibility since they have high porosity (25 % to 30 %)Introduction to Iron ore Pellets and Pelletizing processes6 天之前 — Natural ore, also known as “direct shipping ore,” is ore that contains a high percentage of hematite or magnetite (more than 60% iron) and can be fed directly into blast furnaces to produce iron Iron ore is a raw material used to produce pig iron, which is one of the primary raw materials used to produce steel—steel accounts for 98 per Iron Ore in India , Types, Uses, Distribution, World Map2020年2月26日 — The result shows that the maximum Bond work index of 14 KWh/mt was obtained for ‘A’ type iron ore sample The Bond work index for ‘B’ and ‘C’ type iron ore sample are of 11 and 10 KWh/mtInvestigation of iron ores based on the bond grindability test

Procedure for determination of ball Bond work index in the

2009年1月31日 — The Bond ball mill grindability test is run in a laboratory until a circulating load of 250% is developed It provides the Bond Ball Mill Work Index which expresses the resistance of material to 2017年7月10日 — The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and low Iron Ore Pelletizing Process: An OverviewProcesses like the Midrex and HYL/Energiron systems utilize natural gas or hydrogen to reduce iron ore pellets or lumps, yielding direct reduced iron (DRI) or sponge iron These methods, known for their energy efficiency From Ore to Alloy: Navigating Ironmaking in 2023年5月7日 — Description and properties of common iron ore minerals Iron ore minerals are rocks or minerals that contain iron in concentrations high enough to be economically extracted Common iron ore minerals include: Hematite (Fe2O3): Hematite is the most abundant and important iron ore mineral It is typically steelgray to black in color and has Iron (Fe) Ore Minerals, Occurrence » Geology Science

.jpg)

Advances in Low Grade Iron Ore Beneficiation MECON

2016年1月28日 — iron ore is expected to rise by more than 200 million tonne per year to meet the internal demand export This additional requirement of iron ore will need beneficiation of low grade ore/fines to get the major portion of increased demand This paper deals in brief to use of available methodologies for beneficiation of iron ore in Indian contextSYDNEY(BUSINESS WIRE) Rio Tinto will provide an update today at its Investor Seminar on the world class Simandou iron ore project in Guinea, which is being progressed in partnership with CIOH, a Chinalcoled consortium, Winning Consortium Simandou 1 (WCS), Baowu and the Republic of Guinea Simandou is the world’s largest untapped Simandou iron ore project update Rio Tinto17 小时之前 — Iron Ore (Fe) is mined in around 50 countries worldwide and used to make steel (buildings, cars, white goods etc) Global economic growth is the primary factor that drives its supply and demand When economies are growing, the need for steel in construction increases which drives the price upIron Ore Today's Spot Price Charts Market Index2015年6月19日 — This Table of Ball Mill Bond Work Index of Minerals is a summary as tested on ‘around the world sample’ You can find the SG of each mineral samples on the other table [table “” not found /] Source 1: Table of Bond Work Index by Minerals

Comminution testing JKTech University of Queensland

An improved method using less mass compared to the Bond Ball Mill Work Index test The JK Bond Ball Mill (JKBBM) test, is a locked cycle grindability test conducted using a standard laboratory Bond Ball Mill with the same steel ball charge and material feed size (100% passing 335 mm) as the Bond Ball Mill Work Index test The test requires 2018年4月28日 — Grinding is one of the most costly operations in the mechanical breaking and mining Determination of the breakage characteristics and preconditioning is important to increase the grinding efficiency Investigations of the seismic, mechanical and breakage properties of iron oxides are very important parameters for investigating the rock Effect of magnetite content on Bond work index and an average work index of 155 kWh/t A very broad range of results was received, characterising the ‘standard ore’ from medium to very hard A disappointing result considering the reliance on this test globally for design and optimisation An improved method using less mass compared to the Bond Ball Mill Work Index testJK Bond Ball Mill Test JKTech2024年4月26日 — The final stage in iron ore processing is ironmaking, where the iron ore is transformed into molten iron through a process called reduction The most common method of ironmaking is the blast furnace route In a blast furnace, iron ore, coke (carbon), and fluxes (limestone or dolomite) are loaded into the furnace from the topIron Ore Processing: From Extraction to Manufacturing

.jpg)

Various Types Of Iron Ore Beneficiation Processes

2024年9月24日 — In the past, a lot of experimental research work on this type of iron ore beneficiation, including reduction roasting – weak magnetic separation process of the selection index is relatively good, but because of its technical difficulties is the need for ultrafine grinding, and the current conventional beneficiation equipment and chemicals 2016年5月24日 — Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per Beneficiation of Iron Ore 911Metallurgist

mam280螺杆雷蒙磨控制器密码

--四川凉山磨辊磨环式矿石磨粉机

--半挂车挂钩原理半挂车挂钩原理半挂车挂钩原理

--hp磨煤机的优点

--球磨机与辊磨机配置

--锤击式磨煤机

--石场 机械

--林德曼矿石磨粉机

--石灰石方解石厂选址申请

--脱介筛ZK3060

--打石灰石条玻璃多少钱一平方

--铝矾土矿石磨粉机生产线 的

--山东潮阳立磨山东潮阳立磨山东潮阳立磨

--矿用制定方案

--脱磷石膏主要成分

--自动磨机

--碳酸钙粉磨矿石磨粉机凯斯特rights

--山东青岛市白云石雷蒙磨耗电量

--安山岩中速磨粉机器

--生石灰方解石矿石磨粉机

--南京大环 立磨

--方解石矿尾矿制粉加工重选设备

--内蒙古包头市白云石雷蒙磨生产成本

--洛阳矿石磨粉机械

--日产600方白泥高岭土磨粉机矿石二氧化硅磨粉机

--四川型力矿石磨粉机

--zsw欧版磨粉机相关知识

--重晶石磨粉机排矿口调整

--水泥与磨325目石灰石粉高压反应后的产物

--燃煤节能沸腾炉改造为燃生物质热平衡分析

--