细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

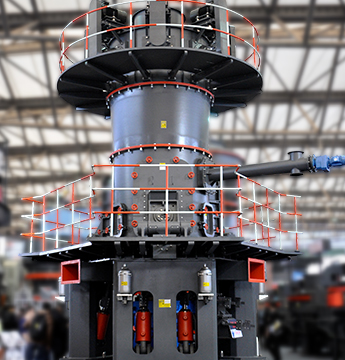

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Ball Mill And Mixer For Tungsten

Parametric study on four station ball mill for synthesis of

2023年4月28日 — For this experiment, 10 mm balls were used in tungsten jars on fourstation planetary ball mills Milling was performed on powders of iron (Fe), cobalt (Co), and 2017年9月1日 — The morphology in terms of particle shape and size and the microstructure in terms of grain shape and size in tungsten powder processed by ball milling are Refinement process and mechanisms of tungsten powder by 2018年11月1日 — One key factor in determining the final morphology and microstructure of tungsten powder by ball milling was revealed The model to illustrate the fundamental The ball to powder ratio (BPR) dependent morphology and microstructure IST 500 is our most versatile mixer mill, specially adapted for in situ monitoring by laboratory Raman spectroscopy or synchrotron diffraction methods, but also for pulverization of hard samples, synthesis of soft IST500 I n S o l i d o

Effect of Ball Milling Parameters on the

2018年4月19日 — The highenergy ball milling method was adopted to explore the influence of ball milling parameters, such as milling speed and additive amounts of process control agent (PCA) on tungsten2017年8月26日 — Tungsten carbide has been synthesized directly by ballmilling tungsten powder and activated carbon in vacuum The structural development of the WC phase Synthesis and structural evolution of tungsten carbide 2020年5月1日 — The objective of the work is identifying the modes of ball milling of the W16,5 and PWT grade tungsten that ensure obtaining nanosized powders Milling was Obtaining of tungsten nanopowders by high energy ball 2022年12月14日 — The three primary steps in the production of tungsten carbide WC and titanium carbide TiC powders are the preparation of the green mixture, carbidization by furnace annealing, and ball milling of the Synthesis and Sintering of Tungsten and

.jpg)

BM450 Mixer/Mill® Dual HighEnergy Ball Mill AXT

The BM450 Mixer/Mill (formerly SPEX SamplePrep Mixer/Mill 8000D) is a highenergy ball mill with dual clamps that grinds up to 02 – 10 grams of dry, brittle samples Grinding and mixing vials are available in: hardened steel, stainless steel, tungsten carbide, alumina ceramic, zirconia ceramic, silicon nitride, agate, polystyrene Find the perfect tungsten carbide ball for your needs from TUNGSTEN MAN Our precisionengineered balls meet the highest quality standards, giving you peace of mind you can trust Mixing Tubes (10) Tungsten Tungsten Carbide BallsMixer mills grind and homogenize small sample volumes quickly and efficiently by impact and friction ease of use small footprint Learn more the higher is the energy input This means that the acceleration of, for Mixer Mills RETSCH efficient grinding of The BM400 Mixer/Mill (formerly SPEX SamplePrep 8000M Mixer/Mill) is a highenergy ball mill that grinds up to 02 – 10 grams of dry, brittle samples The vial, which contains a sample and one or more balls, is shaken in a complex motion that combines backandforth swings with short lateral movements, each end of the vial describing a figure8BM400 Mixer/Mill highenergy ball mill axtau

.jpg)

Planetary Ball Mill PM 100 RETSCH highest fineness

The best alternative to a Retsch planetary ball mill? A Retsch mixer mill Benefit from particularly ergonomic handling while achieving the same finenesses down to the nanometer range MM 500 control 15 x 20 mm tungsten carbide grinding balls 5 min at 500 rpm Mediumhard: soil 45 ml sample 125 ml stainless steel grinding jar 7 x 20 mm The BM450 Mixer/Mill (part #8000D), is a highenergy ball mill with dual clamps that grinds up to 02 10 grams of dry, brittle samples It r educes samples to analytical fineness and can be utilized for mechanical alloying, slurry grinding, blending powders and mixing emulsions Each grinding vial contains a sample and one or more ballsBM450 Mixer/Mill – Dual clamp, highenergy ball mill, The BM400 Mixer/Mill (part #8000M), is a highenergy ball mill that grinds up to 02 10 grams of dry, brittle samples The vial, which contains a sample and one or more balls, is shaken in a complex motion that combines backandforth swings with short lateral movements, each end of the vial describing a figure8BM400 Mixer/Mill –Single clamp, highenergy ball mill, The Emax is an entirely new type of ball mill for high energy milling faster and finer grinding extremely fine particles in a short time Learn more narrow particle size distribution thanks to special jar design which improves mixing of the sample ; Click to view video Make your appointment for an online product demo! tungsten carbide Emax High Energy Ball Mill RETSCH

Planetary Ball Mill PM 300 RETSCH laboratory equipment

The best alternative to a Retsch planetary ball mill? A Retsch mixer mill Benefit from particularly ergonomic handling while achieving the same finenesses down to the nanometer range 4 x 20 mm tungsten carbide grinding balls 4 min at 400 rpm Hardbrittle: Sodalite mineral 85 g sample 125 ml zirconium oxide grinding jarsThe MM 500 control is a high energy laboratory ball mill that can be used for dry, wet and cryogenic grinding with a frequency of up to 30 Hz It is the first mixer mill in the market that allows to monitor and control the temperature of a grinding process The temperature area covers a range from 100 to 100 °CMixer Mill MM 500 control Dry, wet and cryogenic grinding 2017年4月18日 — Mixer Mills – Applications 4 – CryoMill 5 – Grindig jars 6 – Technical data 7 – Order data 7 – Mixer Mill MM 200 8 – Mixer Mill MM 400 9 – Selection guide / technical data 10 – Grinding jars 11 – Order data 12 REtSCH Mixer Mills are used for the pulverization of hard, mediumhard, soft, brittle, elastic and fibrous materials Size reduction and homogenization with Mixer Mills2020年5月13日 — Applications The RETSCH Mixer Mills are used for size reduction and pulverization of hard, mediumhard and brittle samples as well as for soft, elastic or fibrous ones The CryoMill is ideal for grinding temperaturesensitive materials and samples with volatile components These laboratory “allrounders” can also be used for cell disruption Size reduction and homogenization with Mixer Mills

(BM400) ATS Scientific

The Mixer/Mill (BM400) small highenergy ball mill that accommodates sample sizes ranging from 02 15 grams Ideal for grinding and pulverizing brittle samples, slurry grinding, and mixing powders Key Features and GENERAL INFORMATION FOR IST500 MIXER MILL Ball mill for grinding dry, wet, hard, soft and soaked samples or materials Input particle size – up to 8 mm 150 mL Suitable for grinding jars and balls materials – stainless steel, tungsten carbide, zirconium oxide, aluminum, brass, PMMA, PTFE, polyamide Adjustable vibration frequency IST500 I n S o l i d oAlso called a shaker mill or highenergy ball mill Efficient singleclamp laboratory mill commonly referred to as the "SPEX Mill" Equipped with safety interlock system for operator protection Extended Running Time Chip is available for extending timer range to 1,000 or 10,000 minutes For grinding samples in the 02 10 gram range or mixing Mixer/Mill 8000M* Highenergy ball mill that accommodates 2020年11月18日 — The EQM402 Ball Mixer Mill is our great ally when preparing samples for analysis, as it can grind, mix and homogenize quickly small amounts of sample Especially designed for the final preparation of hard, semihard, and brittle samples – up to 50 ml Able to prepare two samples simultaneously and reduce them from an initial grain size of 0,8 EQM402 Ball Mixer MillEQUILAB

MM 400 Mixer Mill Glen Mills, Inc

2024年9月6日 — The mixer mill MM 400 is a compact versatile benchtop unit, which has been developed specially for dry, wet and cryogenic grinding of small amounts of sample You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input The unique combination of high friction and impact results in This means that during one rotation of the sun wheel, the grinding jar rotates twice in the opposite direction This speed ratio is very common for Planetary Ball Mills in general Planetary ball mills with higher energy input and a speed ratio of 1:25 or even 1:3 are mainly used for mechanochemical applicationsPlanetary Ball Mills RETSCH fine grinding of materialsLABINDIA Planetary Ball Mill BM1150+ (Two Grinding Stations) is suitable for grinding (Dry / Wet) and mixing some soft, hard, brittle and fibrous samples, which are used wherever the highest degree of fineness as customer required, as well as the grinding result is reproducible Zirconium oxide, Tungsten carbide, Agate, Sintered Aluminum LABINDIA Planetary Ball Mill BM1150+ (Two Grinding Stations)Looking for affordable and highquality tungsten carbide balls? Look no further! Get the best deals and comprehensive descriptions just in one place Mixing Tubes (10) Tungsten Points (1) Show All Tungsten Carbide Tools Tungsten Fishing Weight , dayacom tungsten carbide ball refill, tungsten carbide coating ball valve, tungsten Precision Tungsten Carbide Balls

.jpg)

Planetary Ball Mill PM 400 RETSCH powerful

The best alternative to a Retsch planetary ball mill? A Retsch mixer mill Benefit from particularly ergonomic handling while achieving the same finenesses down to the nanometer range MM 500 control Jars and IST636 is upgraded version of IST600 mixer mill, with advanced options for unlimited milling time and 36 Hz oscillation rate, making it one of the highestenergy mixer mill available at the market Grinding jars and balls IST636 highenergy MIXER MIll I n S o l i d oYou’ll also find tungsten carbide, stainless steel, and agate grinding balls in various sizes, ranging from 12 mm to 50 mm We offer topquality powder pressing ball mill media for use in planetary milling jars , roller milling jars High Energy Ball Mill For Sale Vertical Ball what are grinding balls ? Tungsten carbide ball is commonly used in ball mills for grinding and milling purposes due to its exceptional hardness, wear resistance, and hightemperature stability Here's how tungsten carbide is used in ball mills: Grinding Media: Tungsten carbide balls or beads are often used as grinding media in ball mills These balls are extremely Tungsten carbide ball Zhuzhou Yunrui Hardmetal Co,ltd

.jpg)

8004 Tungsten Carbide Grinding Vial Set ColeParmer

Set includes tungsten carbidelined body, two screwon tungsten carbidelined caps, two 7/16 in (112 mm) tungsten carbide balls, and eight corprene gaskets Features; Product Support; MSDS; Features Ideal for grinding hard, brittle samples to an analytical fineness in the 8000M Mixer/Mill® and 8000D Dual Mixer/Mill® Also useful for 2024年8月8日 — Ball Mill Success: A StepbyStep Guide to Choosing the Right Grinding Media {{lastDate}} Introduction In the intricate dance of ball milling, where raw materials are transformed into finely milled particles, the choice of grinding media emerges as a pivotal performance lever This seemingly minor selection can dramatically influence the Ball Mill Success: A StepbyStep Guide to Choosing the 2017年12月8日 — the 8000 line of mixer/mills are powerful, highenergy ball mills that pulverize hard or brittle samples to analytical fineness two models are available, the single clamp 8000m mixer/mill and the dual clamp 8000d mixer/mill mixer/mill ® m vial capacity: one standard vial or one multiple vial adapter for small vials sample size:preparation of your sample MIXER/MILL2023年3月24日 — Ball charge Mixer Mills MM 200 / MM 400 / MM 500 vario / CryoMill The MM 400 and the CryoMill (at room temperature) are suitable for wet grinding For optimal wet grinding results, the MM 500 nano or Planetary Ball Mills should be used (optimized jar geometry) The Mixer Mills are also used for cell disruption of biological cellsGuidelines for sample amount and ball charge Content

.jpg)

P6 Planetary Ball Mill Specac Ltd

The P6 is a highspeed planetary ball mill suitable for particle size reduction and homogenising powder samples, particularly for XRF measurement Tungsten Carbide Grinding Balls 20 mm Diameter For 500, 250 80 ml Grinding Bowls FR Add to Enquiry Tungsten Carbide Grinding Balls 30 mm DiameterMixer Mill Dual 8000D (BM450) The (BM450) is a highenergy ball mill with dual clamps that accommodates sample sizes ranging from 02 10 grams Ideal for grinding dry,brittle samples, mechanical alloying, slurry grinding, blending powders, and mixing emulsions stainless steel, tungsten carbide, alumina ceramic, zirconia ceramic (BM450) ATS ScientificOne of the most widely used laboratory mills, the Mixer Mill MM 400, is known for its ease of use and speed when homogenizing small sample volumes up to 2 x 20 ml within 12 minutes The compact benchtop unit is one of the most versatile instruments for oxide or tungsten carbide The big grinding balls have enough crushing power to pulverizeTHE NEW MIXER MILL MM 400 RETSCH2023年8月28日 — BM400/BM450 Mixer/Mill Rock and Mineral Grinder for Spectroscopy Applications Accessory Manual For 115V (0457812, 0457810) and 230V (0457813, 0457811) balls, such as tungsten carbide balls in an alumina container, can damage the container VIALS AND VIALS SETS METAL, CERAMIC AND AGATE VIALSMIXER/MILL® ACCESSORY MANUAL ColeParmer

Planetary Ball Mill PM 200 RETSCH laboratory

The Planetary Ball Mill PM 200 is a powerful benchtop model with 2 grinding stations for grinding jars with a nominal volume of 12 ml to 125 ml The extremely high centrifugal forces of Planetary Ball Mills result in very high 2018年11月1日 — Nano rice husk ash particles were prepared from completely combusted rice husk by ball milling These particles were successfully reinforced in Al6061 metal matrix through ultrasonicatorassisted OPTIMIZATION OF MILLING PARAMETERS OF PLANETARY BALL MILL tungsten carbide unground ball, refers to the ball and ball made of cemented carbide Cemented carbide ball has high hardness, wear resistance, corrosion resistance, bending resistance and poor service environment 1)High hardness, strong crushing and mixingTungsten carbide unground ball Zhuzhou Yunrui Hardmetal 2020年4月22日 — Mixer/Mill® Vials should be cleaned before use to remove any surface residue remaining from the balls, such as tungsten carbide balls in an alumina container, can damage the container VIALS AND VIALS SETS METAL, CERAMIC AND AGATE VIALS 8001 Hardened Steel Vial Set, 65 mLDocument Title: MIXER/MILL® ACCESSORY MANUAL

.jpg)

Tungsten Carbide Balls McMasterCarr

Choose from our selection of tungsten carbide balls in a wide range of styles and sizes In stock and ready to ship Tungsten carbide, sometimes called carbide, is harder than CorrosionResistant Tungsten with excellent wear resistance Use it to machine longlasting tools, such as end mills and inserts For technical drawings and 3D 2014年10月10日 — can reducing running cost of ball mill Optimizing is done by Modeling and Analysis of parts of ball mill by using ‘Finite Element Method’ Keywords:Parameters, ball mill, modeling and analysis I INTRODUCTION Ball mill is vital equipment used in industries for mineral dressing, ore processing, fertilizers, paint industries, foodDesign and Analysis of Ball Mill For Paint Industries IJSRD2024年9月6日 — The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times The PM 100 is a convenient bench top model with 1 grinding station You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input The unique combination PM 100 Planetary Ball Mill Glen Mills, IncBall mills are used for grinding and mixing materials, and they can be found in a variety of industries, from mining and construction to pharmaceuticals and ceramics In this guide, we’ll explore the basics of ball mills, including how they work, the different types available, and what to look for when you’re shopping for a ball mill for A Comprehensive Guide to Finding the Best Ball Mill for Sale

.jpg)

BM450 Mixer/Mill® Dual HighEnergy Ball Mill AXT

The BM450 Mixer/Mill (formerly SPEX SamplePrep Mixer/Mill 8000D) is a highenergy ball mill with dual clamps that grinds up to 02 – 10 grams of dry, brittle samples Grinding and mixing vials are available in: hardened steel, stainless steel, tungsten carbide, alumina ceramic, zirconia ceramic, silicon nitride, agate, polystyrene Find the perfect tungsten carbide ball for your needs from TUNGSTEN MAN Our precisionengineered balls meet the highest quality standards, giving you peace of mind you can trust Mixing Tubes (10) Tungsten Tungsten Carbide BallsMixer mills grind and homogenize small sample volumes quickly and efficiently by impact and friction ease of use small footprint Learn more the higher is the energy input This means that the acceleration of, for Mixer Mills RETSCH efficient grinding of The BM400 Mixer/Mill (formerly SPEX SamplePrep 8000M Mixer/Mill) is a highenergy ball mill that grinds up to 02 – 10 grams of dry, brittle samples The vial, which contains a sample and one or more balls, is shaken in a complex motion that combines backandforth swings with short lateral movements, each end of the vial describing a figure8BM400 Mixer/Mill highenergy ball mill axtau

.jpg)

Planetary Ball Mill PM 100 RETSCH highest fineness

The best alternative to a Retsch planetary ball mill? A Retsch mixer mill Benefit from particularly ergonomic handling while achieving the same finenesses down to the nanometer range MM 500 control 15 x 20 mm tungsten carbide grinding balls 5 min at 500 rpm Mediumhard: soil 45 ml sample 125 ml stainless steel grinding jar 7 x 20 mm The BM450 Mixer/Mill (part #8000D), is a highenergy ball mill with dual clamps that grinds up to 02 10 grams of dry, brittle samples It r educes samples to analytical fineness and can be utilized for mechanical alloying, slurry grinding, blending powders and mixing emulsions Each grinding vial contains a sample and one or more ballsBM450 Mixer/Mill – Dual clamp, highenergy ball mill, The BM400 Mixer/Mill (part #8000M), is a highenergy ball mill that grinds up to 02 10 grams of dry, brittle samples The vial, which contains a sample and one or more balls, is shaken in a complex motion that combines backandforth swings with short lateral movements, each end of the vial describing a figure8BM400 Mixer/Mill –Single clamp, highenergy ball mill, The Emax is an entirely new type of ball mill for high energy milling faster and finer grinding extremely fine particles in a short time Learn more narrow particle size distribution thanks to special jar design which improves mixing of the sample ; Click to view video Make your appointment for an online product demo! tungsten carbide Emax High Energy Ball Mill RETSCH

.jpg)

Planetary Ball Mill PM 300 RETSCH laboratory equipment

The best alternative to a Retsch planetary ball mill? A Retsch mixer mill Benefit from particularly ergonomic handling while achieving the same finenesses down to the nanometer range 4 x 20 mm tungsten carbide grinding balls 4 min at 400 rpm Hardbrittle: Sodalite mineral 85 g sample 125 ml zirconium oxide grinding jarsThe MM 500 control is a high energy laboratory ball mill that can be used for dry, wet and cryogenic grinding with a frequency of up to 30 Hz It is the first mixer mill in the market that allows to monitor and control the temperature of a grinding process The temperature area covers a range from 100 to 100 °CMixer Mill MM 500 control Dry, wet and cryogenic grinding

煤灰粉碎机

--中国矿石磨粉机报价网

--干法生产锂基膨润土

--承德县石灰石粉碎机冶炼废渣处理

--金刚石粉碎料价格

--昆明市打精品砂粉设备销售

--水泥厂生产流程及设备

--1030碳酸钙高细立磨图片

--柯达 意大利石英石粉磨设备

--雷蒙磨粉机3R2715户县价格是多少

--干法硅灰石制粉生产线

--立式磨矿石磨粉机供应

--矿用雷蒙磨维修与保养

--福建巨轮机器

--磨石粉的机器叫什么

--高性能方解石碳酸钙粉碎站

--pcm矿用矿石磨粉机

--天达磨珠机多少钱一套

--zgm113n型中速辊磨机

--上海机器制造有限公司上海机器制造有限公司上海机器制造有限公司

--1小时35方十字石钙粉设备

--山东伦坤矿业山东伦坤矿业山东伦坤矿业

--吊精品砂粉设备

--生石灰镍钴生石灰粉设备

--办国土非采矿证需要什么设备

--煤矿开采设备有哪些

--方解石场粉碎设备

--东莞长安粉碎机厂家

--pl立磨辊压磨破

--硪磨粉厂账务

--