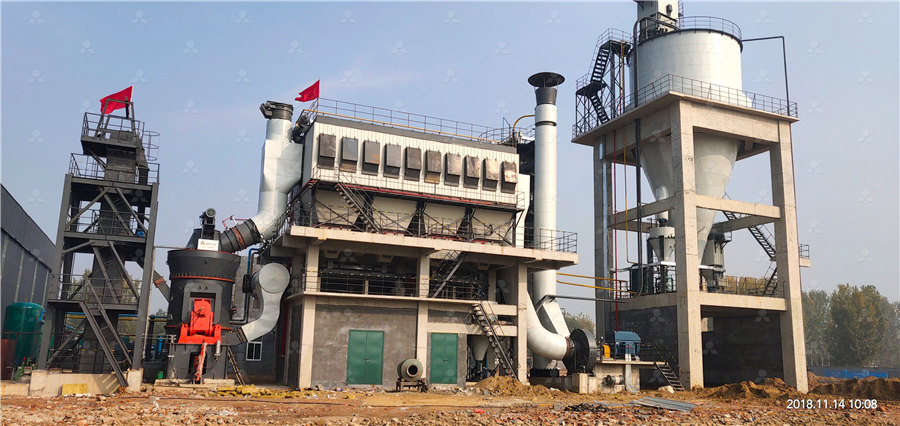

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

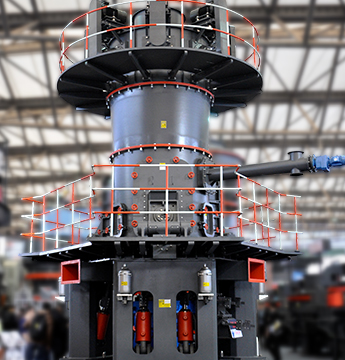

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Widely Used Cement Grinding Mill

.jpg)

Cement mill, Cement grinding mill All industrial

Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed This machine can be can grind all kinds of ores and other materials, which is widely used The Center Peripheral Discharge rod mill is also used for wet grinding but produces a coarser product than the overflow type Either the End or Center Peripheral discharge Grinding Mills 911Metallurgist2016年10月5日 — In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equip‐ ments and comparisons over EnergyEfficient Technologies in Cement Grinding2020年5月1日 — Nowadays, ball mills are used widely in cement plants to grind clinker and gypsum to produce cement In this work, the energy and exergy analyses of a cement Energy and exergy analyses for a cement ball mill of a new

CFB石灰石脱硫剂制备64.jpg)

Energy and exergy analyses for a cement ball mill of a new

2020年2月1日 — Nowadays, ball mills are used widely in cement plants to grind clinker and gypsum to produce cement In this work, the energy and exergy analyses of a cement Ball mills for fine grinding cement clinker and additives are widely used around the world To improve the efficiency of a ball grinding the ball mills are transferred in closed circuit with Analysis of the efficiency of the grinding process in 2017年5月19日 — [Show full abstract] importance to lower impact on environment and maintain cement quality and performance Grinding aids are widely used to enhance mill output, improve fineness andOverview of cement grinding: fundamentals, 2011年2月1日 — Closed circuit vertical roller mill grinding In this study, a compact design and partial external recycling type vertical roller mill circuit was sampled VR mills are widely Comparison of the overall circuit performance in the cement

Cement Equipment, Cement Plant Equipment

AGICO CEMENT can manufacture cement equipment including cement crusher, raw mill, cement kiln, cement mill and others, which can be widely used in cement crushing plant, cement clinker plant, cement grinding Widely Used Limestone Gypsum Calcium Carbonate Quartz Silica Sand Grinding Dry Ball Mill Cement Coal Feldspar Dolomite Ball Mill, You can get more details about Widely Used Limestone Gypsum Calcium Carbonate Quartz Silica Sand Grinding Dry Ball Mill Cement Coal Feldspar Dolomite Ball Mill from mobile site on AlibabaWidely Used Limestone Gypsum Calcium Carbonate Quartz Cement ball mill is a kind of cement grinding equipment commonly used in cement plants It is mainly used for grinding materials in cement clinker section Cement ball mill is widely used in cement production, silicate Use Cement Ball Mill Grinding Cement Clinker2016年1月1日 — Ball mills for fine grinding cement clinker and additives are widely used around the world To improve the efficiency of a ball grinding the ball mills are transferred in closed circuit with air Analysis of the efficiency of the grinding process in closed

.jpg)

Cement Grinding Cement Plant Optimization

Cement grinding operation may be performed in one of the following mill setups Ball and tube mills Vertical Roller Mills (VRM) Roller press with Ball mill Ball Mill Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical 2023年11月24日 — The cement and pharmaceutical industries normally use dry grinding whereas the mineral processing industry mostly resorts to wetmilling the overflow discharge mill, which is most widely used due to its simplicity, has material fed through the trunnion at one end and discharged through another trunnion at the other end as Grinding Media in Ball Mills for Mineral Processing2021年4月27日 — The consumption of energy by the cement grinding operation amounts to one third of the total electrical energy used for the production of cement The optimization of this process would yield substantial benefits in terms of energy savings and capacity increase Optimization of the Cement Ball Mill OperationOPTIMIZATION OF CEMENT GRINDING OPERATION IN 2019年1月3日 — Clinker grinding technology is the most energyintensive process in cement manufacturing Traditionally, it was treated as "low on technology" and "high on energy" as grinding circuits use more than 60 per cent of total energy consumed and account for most of the manufacturing cost Since the increasing energy cost started burning the benefits Clinker grinding technology in cement manufacturing

.jpg)

What is a Ball Mill? Economy Ball Mill

2023年6月12日 — A ball mill is a type of grinder that uses metal balls or other grinding mediums to reduce the size of various materials The material to be ground is placed in a cylindrical container that spins on its axis The metal balls or grinding media inside the container hits the material and breaks it down into smaller particlesCement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders Cement ball mill and vertical roller mill are two most widely used cement mills in today’s cement grinding plants and are also the main types of cement mill we produce As a professional cement equipment manufacturer, AGICO has rich Cement Mill for Sale Buy Cement Ball Mill AGICO Cement 2020年2月1日 — Nowadays, ball mills are used widely in cement plants to grind clinker and gypsum to produce cement In this work, the energy and exergy analyses of a cement ball mill (CBM) were performed and Energy and exergy analyses for a cement ball mill of a new 2017年5月19日 — Grinding aids are widely used to enhance mill output, improve fineness and reduce energy consumptionPerformance enhancers permit to boost clinker reactivity Chromium reducers are mandatory Overview of cement grinding: fundamentals,

Grinding Mill Grinding Equipment Cement

Grinding mills are mainly used to grind the clinker and raw materials in the cement plant It is also called cement grinding equipment or cement mill It is widely used in the cement plant and electric power industry because of 2013年2月1日 — To investigate the effects of grinding media shapes on the grinding kinetics of ball mill cement clinker, the grinding effects with ϕ20 mm balls and ϕ20 × 20 mm cylinders on six different size The effects of grinding media shapes on the grinding kinetics of cement 2012年6月1日 — Mill – Cement and Concrete Research, V ol 33, 2003, 439445 16 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation(PDF) Grinding in Ball Mills: Modeling and Process Control2021年5月10日 — Cement mill is widely used in the cement and silicate, new building materials, refractory material, chemical fertilizer, the dressing of black and nonferrous metal, glassceramic and other industries With other names of cement grinder and cement grinding machine, the cement mill owns multiple cabin separating boards which do better Cement MillGrinding MachineryCement Ball MillCement Grinder

.jpg)

Widely Used Limestone Gypsum Calcium Carbonate Quartz

Widely Used Limestone Gypsum Calcium Carbonate Quartz Silica Sand Grinding Mill Cement Coal Feldspar Dolomite, You can get more details about Widely Used Limestone Gypsum Calcium Carbonate Quartz Silica Sand Grinding Mill Cement Coal Feldspar Dolomite from mobile site on Alibabao Generally 2/3 of the electricity consumed is used in the grinding of raw materials, fuels finished cement; o Finished grinding may consume 25 – 50 kWh/t cement, depending on the feed material grindability, additives used, plant design especially the required cement fineness Cement grinding is the single biggest consumer of electricity Improvements in New Existing Cement Grinding Mills by Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plantsThe function of the separator is to separate the finesized particles from the coarsesized particles, so as to avoid material condensation and over grinding in the mill, and improve the milling Cement Milll Separator Cyclone Air Separator in Cement PlantAs a grinding medium, grinding balls are widely used in the grinding industry, such as concentrators, cement plants, thermal power plants, refractory material factories, etc In the Chinese market, about 4 million tons of steel balls are consumed every year, and buyers should carefully compare the material and use the scientific ratio when buyingGrinding Ball Ball Mill Balls For Sale Ball Mill Media Cement

Review on vertical roller mill in cement industry its

2021年1月1日 — The clinker cools further naturally in CSP and extracted and sent through deep pan conveyors to Cement mill for final finished grinding [1], [2], [9], [14] 25 Ball mills have been used as the main grinding tool for cement production for over 100 years Although easy to operate and competitive compared to other technologies, the poor Clinker Grinding The cement clinker is ground as finished cement, in a vertical roller mill for cement or in ball mills similar to those normally used for grinding hard raw materials in dry and semidry processes However, the cement clinker is more difficult to grind than raw materials and must also be finer groundAn Introduction to Clinker Grinding and Cement StorageThe Raymond bowl type ring mill [148] for coal dryinggrinding is widely used in the American cement industry This mill has all the characteristic features of the roller mills described above; it consists essentially of a Roller mills INFINITY FOR CEMENT EQUIPMENT2024年1月28日 — 1 Cylindrical Shell: The ball mill consists of a hollow cylindrical shell that rotates about its axis The shell is usually made of steel, stainless steel, or rubber 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding actionBall mill: Principles, construction, working, uses, merits, and

Cement Euipment Overview Cement Making Machines Cement

2019年9月27日 — Firstly, cement mill is used to grind the crushed material into fine size before clinker production A cement mill is also applied for grinding clinker into finished cement The cement clinker grinding is the last step of the cement manufacturing process, in this step, cement mill grinds cement clinker, gelatinizing agent and other materials Vertical raw mill is important equipment widely used in the cement raw meal (cement raw materials) grinding section of the cement production process in cement plantBecause the vertical raw mill is the use of roller grinding principle to crush materials, its vertical raw mill operation is more efficient and energysaving, product output is more stable, so in Vertical Raw Mill for Cement Raw Meal Grinding in Cement Ball mills, also known as tube mills, are widely used in cement, silicate products, new building materials, refractory materials, fertilizers, black and nonferrous metal dressings, and glass ceramics industryAs for types of cement ball mill, there are normal cement ball mill and superfine cement ball millCement Ball Mill Ball Mill For Sale Cement Mill 15100t/h2015年3月10日 — Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals This paper presents an experimental approach to measure and model the residence time distribution of vertical roller mill in cement clinker grinding circuit The dispersion model, tankinseries Copper ore grinding in a mobile vertical roller mill pilot plant

Slag Mill

2024年5月18日 — Overview Our GGBS ball mill is a key grinding machine mainly used to process materials by crushing process, and it is widely used in various manufacture industries, like cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramicsThe grinding media balls in the ball mill are used in cement plant to help grind blocky or granular grindable materials produced in the cement manufacturing process, so as to achieve the effect of grinding Vertical Ball Mill for Sale Mining and Cement Milling 2024年1月18日 — Limestone is the primary raw material for manufacturing cement, lime, and carbide and is an essential flux limestone in the metallurgical industry Highquality limestone, after ultrafine grinding, is How to choose a limestone grinding mill2022年1月20日 — A molecular modified PCEtype GA was selfsynthesized, and the grindability concerning grinding duration and particle size distribution of ground cement was evaluated Setting time, flowability, hydration heat, mechanical properties and microstructure of the ground cement were also investigated The results show that: PCEtype GA is Effects of Polycarboxylatebased Grinding Aid on the

Cement Manufacturing—Technology, Practice, and

2021年11月17日 — The grinding operation of the cement is carried out in cement mills located in the grinding plants The grinding plants can be installed at a far away location from the clinkering plant 26 Cement Dispatch Cement is shipped in bulkers or in packed bags Transport can be by road, railway, and waterways and depends on local conditions2019年4月23日 — The cooled clinker is then ground in a suitable grinding mill with about 5% gypsum or another calcium sulphate source and other trace components such as limestone and stannous or ferrous sulphate Adding SCMs results in improved strength and durability in the cement composite, and they are widely used in concrete admixtures An overview of alternative raw materials used in cement and Ball mills for fine grinding cement clinker and additives are widely used around the world To improve the efficiency of a ball grinding [13] is widely distributed TSG "BM–DS" with intermediate separation of the products of grinding, allowing to allocate of the total material flow the fine fraction The product separation, as a rule, is Analysis of the efficiency of the grinding process in 4 天之前 — Cement ball mills are mainly used to grind clinker and gypsum into fine powder for cement production They can also be used to grind materials like slag, Ball mills are also widely used for grinding coal, coke, construction materials, glass, silica sand, marble, and other materials 4 Ceramics roductionHighquality Ball Mill with Low price for Kinds of Materials

Cement Ball Mill JXSC Machine

2019年12月10日 — The cement ball mill is mainly used for grinding the finished products and raw materials of cement plants, and is also suitable for grinding various ore and other grindable materials in industrial and mining enterprises such as metallurgy, chemical industry, and electric power Cement grinding unit is widely used in the United States Chromium content: 1% – 28% Hardness: HRC4060 Diameter: 10mm150mm Features: after heat treatment, it has high hardness, grinding resistance and no loss of roundness Application: cast grinding balls are widely used in ball mill grinding systems in mining, cement, building materials, chemical industry and other fieldsSteel Grinding Balls for Sale, Grinding Rods Cylpebs for Grinding MillFinite Element Method (FEM) as a numerical method is widely used as a calculation method in the field of engineering analysis, it gets widely developed with its unique advantages of computing, ANSYS software with its multiphysics field coupled analysis function has become mainstream of software applications and it is widely used in the engineering GLOBAL CEMENT: GRINDING Major vertical roller mill AGICO CEMENT can manufacture cement equipment including cement crusher, raw mill, cement kiln, cement mill and others, which can be widely used in cement crushing plant, cement clinker plant, cement grinding Cement Equipment, Cement Plant Equipment

.jpg)

Widely Used Limestone Gypsum Calcium Carbonate Quartz

Widely Used Limestone Gypsum Calcium Carbonate Quartz Silica Sand Grinding Dry Ball Mill Cement Coal Feldspar Dolomite Ball Mill, You can get more details about Widely Used Limestone Gypsum Calcium Carbonate Quartz Silica Sand Grinding Dry Ball Mill Cement Coal Feldspar Dolomite Ball Mill from mobile site on AlibabaCement ball mill is a kind of cement grinding equipment commonly used in cement plants It is mainly used for grinding materials in cement clinker section Cement ball mill is widely used in cement production, silicate Use Cement Ball Mill Grinding Cement Clinker2016年1月1日 — Ball mills for fine grinding cement clinker and additives are widely used around the world To improve the efficiency of a ball grinding the ball mills are transferred in closed circuit with air Analysis of the efficiency of the grinding process in closed Cement grinding operation may be performed in one of the following mill setups Ball and tube mills Vertical Roller Mills (VRM) Roller press with Ball mill Ball Mill Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical Cement Grinding Cement Plant Optimization

.jpg)

Grinding Media in Ball Mills for Mineral Processing

2023年11月24日 — The cement and pharmaceutical industries normally use dry grinding whereas the mineral processing industry mostly resorts to wetmilling the overflow discharge mill, which is most widely used due to its simplicity, has material fed through the trunnion at one end and discharged through another trunnion at the other end as 2021年4月27日 — The consumption of energy by the cement grinding operation amounts to one third of the total electrical energy used for the production of cement The optimization of this process would yield substantial benefits in terms of energy savings and capacity increase Optimization of the Cement Ball Mill OperationOPTIMIZATION OF CEMENT GRINDING OPERATION IN 2019年1月3日 — Clinker grinding technology is the most energyintensive process in cement manufacturing Traditionally, it was treated as "low on technology" and "high on energy" as grinding circuits use more than 60 per cent of total energy consumed and account for most of the manufacturing cost Since the increasing energy cost started burning the benefits Clinker grinding technology in cement manufacturing2023年6月12日 — A ball mill is a type of grinder that uses metal balls or other grinding mediums to reduce the size of various materials The material to be ground is placed in a cylindrical container that spins on its axis The metal balls or grinding media inside the container hits the material and breaks it down into smaller particlesWhat is a Ball Mill? Economy Ball Mill

Cement Mill for Sale Buy Cement Ball Mill AGICO Cement

Cement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders Cement ball mill and vertical roller mill are two most widely used cement mills in today’s cement grinding plants and are also the main types of cement mill we produce As a professional cement equipment manufacturer, AGICO has rich

承德县石灰石粉碎机冶炼废渣处理

--1680重晶石磨粉机

--生石灰碳酸钙体积变密度

--煤矿立式雷蒙磨

--煤磨执机工

--矿石磨粉机镇江

--甘肃陇南立轴试矿石磨粉机

--煤矿磨石灰石粉碎机

--重晶石磨粉机(型号1306)

--床垫提丝磨粉机器厂

--供矿石磨粉机图纸

--一个大型搅拌站需要多少设备

--2011年全国立磨生产台数

--南非加纳石膏矿石膏矿开采

--方解石粉磨机生产线方解石粉磨机生产线方解石粉磨机生产线

--双进双出磨煤机检修规程

--怎样加工成一级粉煤灰

--温州现在煤多少钱一吨

--1000TPH大产量矿石磨粉机

--立式磨雷蒙磨有什么特点

--中国稀土矿开采的方式

--红色粉煤灰遇水

--菲力博粉碎机 FLB200型

--石膏热导率

--沥青路面灰土垫层套用什么定额

--生石膏应力应变关系

--园行矿石磨粉机

--粉煤灰具体做什么用

--Ball Mill And Mixer For Tungsten

--福建莆田市白云石制粉设备图片

--